How To Repair Surface Mount Pcb

Care needs to be taken when treatment printed circuit boards (PCBs) to foreclose causing more damage than you are repairing. These are bug to be concerned about:

- Article of clothing safety glasses – Solder can splatter or leads tin can wing when trimmed, so wear safe spectacles to protect your eyes anytime you are repairing a PCB.

- Unplug and discharge your electronics – To foreclose short circuiting the electronics and mayhap electrocuting yourself, make sure the device you lot are repairing is unplugged and fully discharged. Capacitors and power supplies can concord a charge, so pay actress attention to brand sure they are fully discharged. If in that location are any supplemental batteries, disengage those too.

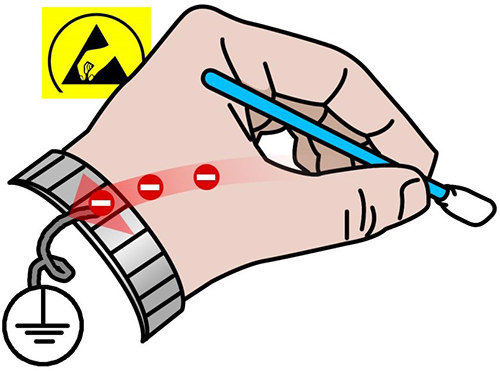

- Forestall static belch – Electrostatic discharge (ESD) is the sudden flow of electrons, or spark, from 1 surface to another. This is caused by a differential between the two surfaces, and so one has more electrons than some other. Nature loves equilibrium, then the electrons are exchanged to equalize the distribution. Wearing a grounded wrist strap and working on a grounded ESD-safe mat is the all-time style to foreclose ESD. A wrist strap has a conductive surface that touches the skin, and so can bleed off excess electrons. An ESD-prophylactic mat works past a similar principle, so bleeds off a accuse from anything on its surface. If working on a PC, yous tin can clip the wrist strap straight to an unpainted area of the example.

- Reduce contamination by washing hands and treatment only the edges of the PCB – Contamination from your hands can create solderability bug and possibly pb to board failure from corrosion or dendritic growth. Silicone in your paw balm or picked up from somewhere tin can create a barrier on contact areas which, in a soldering process, could prevent the solder from creating a adept metallurgic bond. The solder may stick temporarily just pop off when exposed to whatsoever kind of thermal or concrete stress. Contamination, similar salt on those fries yous had with lunch, are another leading cause of problems introduced in the repair process. Table salt is an ionic soil which, when combined with wet from the air, can cause corrosion. The ionic particles can too join to form dendrites, which can atomic number 82 to electric current leakage and fifty-fifty short circuiting. Washing your easily and using only electronic-safe hand lotion is a good fashion to forestall this blazon of board failure. Also holding the lath only by the edges without contacts (east.g. gilt fingers) can assistance preclude depositing contamination on any critical areas.

Associated products:

https://world wide web.chemtronics.com/static-gratuitous-mitt-baby-sit

https://world wide web.chemtronics.com/static-free-mat-and-benchtop-reconditioner

Should I be worried near static electricity with handling PCBs?

Yeah. A typical technician working on a PCB tin generate thousands of volts. SMOS logic devices can be damaged with 250-3000 volts, EPROM devices downward to 100 volts, and microprocessor chips as low equally 10 volts. Damage tin can shut down functions or create intermittent issues, and it can either be catastrophic (immediate) or latent (equally in later "field failure"). (source: Phil Storrs PC Hardware Book)

Electrons are constantly being exchanged equally objects interact with each other. Issues occur when the materials involved don't allow the electrons to flow easily and achieve equilibrium. Called insulators, they tend to collect electrons, which create negatively charged hot-spots on their surfaces.

When these charged hot-spots come in close proximity (not necessarily even directly contact) with another object, a sudden exchange or "belch" tin occur, where electrons are of a sudden exchanged to create equilibrium. That effect is chosen "electrostatic belch" or "ESD".

Electrostatic discharge happens all the fourth dimension, especially in dry climates and in the winter season, when there isn't wet in the air to help bleed off backlog electrons (water is conductive, and so allows the electrons to flow more readily). Normally it is nothing more than than an irritation, but with sensitive electronics, it can lead to PCB failures.

Wearing a grounded wrist strap and working on a grounded ESD-rubber mat is the all-time way to preclude ESD. A wrist strap has a conductive surface that touches the skin, and then can bleed off excess electrons. An ESD-safe mat works by a similar chief, bleeding off any accuse from its surface. If working on a PC, you lot tin clip the wrist strap directly to an unpainted area of the case.

Grounded wrist strap bleeds off excess electrons to prevent dissentious static discharge.

Associated products:

https://world wide web.chemtronics.com/static-free-hand-guard

https://www.chemtronics.com/static-free-mat-and-benchtop-reconditioner

How do I reduce thermal stress on components with repairing or reworking a PCB?

The objective is to heat and remove the solder joint and remove the component equally chop-chop as possible while not heating surrounding areas unnecessarily. Heating only the solder joints required to remove the defective components and performing the task apace reduces thermally stressing other areas. Solder wick or desoldering stations are good methods to remove solder from isolated areas. Methods involving hot plates or hot air have a better hazard of causing PCB failure later on on.

Associated products:

https://www.chemtronics.com/desoldering-braid-wick

How tin solder or components be removed from a PCB?

Can solder exist removed?

How do y'all set up soldering mistakes?

Soldering is a fairly simple concept of combining two metallic surfaces using a hot soldering iron, flux, and solder. Removing the same solder if something isn't right is more than complicated. Bad components may demand to be removed and replaced, or excessive solder may need to be removed, like with bridging between two contacts.

The following are common methods of solder removal, also called "desoldering":

- Solder wick – Solder wick, desoldering wick, or just "wick" are all names for a copper complect that is used to absorb solder. It is generally coated with flux and so that when heated solder is melted, drawn upwardly, and retained using a combination of wetting and capillary action. Solder wick allows y'all to remove solder in isolated areas without thermally stressing the overall lath or nearby components. Solder wick tin can only remove exposed solder, so components roofing contact areas, like ball grid arrays (BGAs), have to be removed before the residue solder can exist removed.

- Solder suckers – Solder suckers utilise a spring-loaded vacuum to depict up melted solder. The solder needs to be melted either with a soldering iron or hot air, like from a estrus gun or rework station. Only small amounts of solder are fatigued upward at a time, or it often takes multiple attempts to remove a component. Maintaining soldering temperature or remelting a solder joint over-and-over increases the thermal stress on components, other solder joints, and the overall circuit board. Solder suckers can only remove exposed solder, so components roofing contact areas, like brawl filigree arrays (BGAs), have to be removed before the residue solder can be removed.

- Desoldering stations – Desoldering stations have a soldering tip with a hole in the middle that draws upwardly the solder one time it is melted. While a very efficient method of desoldering, rework stations can only remove exposed solder so components covering contact areas, like ball grid arrays (BGAs), have to be removed before the residual solder can be removed.

- Hot air solder stations – These stations blow hot air over the repair surface area to melt the solder, and the component is removed either with tweezers or a vacuum lifter. Once the component is out of the way, the solder will need to be removed another way.

- Hot tweezers – If you picture grabbing the lead areas with a tweezer made of ii soldering irons, you get the general idea. The idea is to clench onto the leads on both sides of the component to melt all the solder at once. This limits the overall thermal stress compared to hot air. Once the component is out of the fashion, the solder will need to be removed another manner.

- Hot plate – Placing the PCB on a hot plate melts (or reflows) all the solder joints to let several components to be removed at the same fourth dimension. This method may unnecessarily stress other components and the board as a whole.

Associated products:

https://world wide web.chemtronics.com/desoldering-braid-wick

What is solder wick?

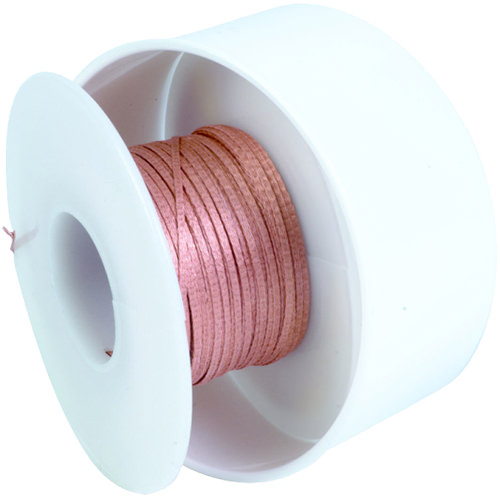

Solder wick, desoldering braid, or just "wick" are all names for a copper braid that is used to absorb solder. Information technology is generally coated with flux so that when heated the solder is melted, drawn up, and retained using a combination of wetting and capillary action. Solder wick allows you to remove solder in isolated areas without thermally stressing the overall lath or nearby components. Solder wick can only remove exposed solder, and so components covering contact areas, like ball grid arrays (BGAs), take to be removed earlier the balance solder can be removed.

Solder wick comes in a broad diversity of widths to efficiently remove solder from unlike types of contact areas. Solder wick mostly comes coated with flux that tin can be matched to your original soldering process: rosin, no-make clean, or unfluxed to add your own flux equally you use it.

Close up of copper solder wick

Associated products:

https://www.chemtronics.com/desoldering-braid-wick

How practice I utilise solder wick?

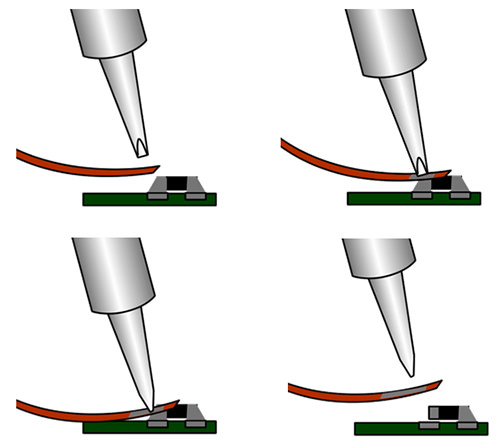

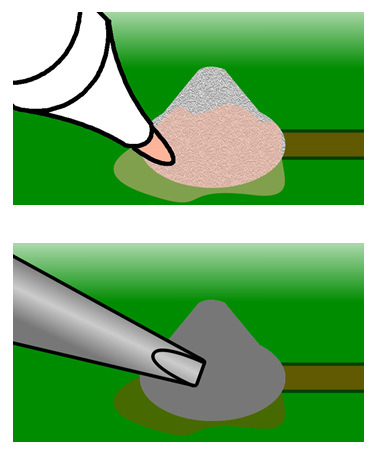

- Identify the complect over unwanted solder, preferably on the greatest solder build up and so that it maximizes the contact of the braid to the surface area of the solder.

- Next place your atomic number 26 tip over the wick at 45 degrees and allow rut to transfer to the pad. Molten solder will blot into the braid.

- Move the solder tip and braid as needed to remove all of the solder at one time. Be careful not to drag the braid over the pads equally it could scratch.

- Once the braid is full of solder, you must trim the spent portion and move to fresh complect in order to pull more solder. Remove the iron and braid simultaneously to avert soldering the wire to the lath.

Associated products:

https://world wide web.chemtronics.com/desoldering-braid-wick

Why are at that place and so many different kinds of solder wick?

Solder wick comes in a broad variety of widths to efficiently remove solder from different types of contact areas and is coated with a diverseness of flux that can be matched to your original soldering process

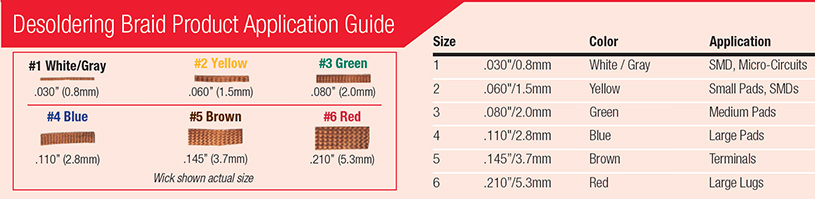

Common sizes of solder wick:

Wick that is too thin won't remove enough solder and requires you lot to trim and remelt the solder over and over. Wick that is besides wide takes longer to oestrus and may interfere with other components on the circuit board.

Cull a desoldering wick width that closely matches the size of the contact area. This will ensure that you get proper estrus conduction and that y'all don't desolder unwanted areas. Widths of desoldering wire are designated by the numbers 1 through 6 or by color codes, and these are standard across the industry.

- #1/white braid is the smallest (under 1mm wide) and is mainly for SMD'due south and microcircuits.

- About will observe #ii/yellow, #3/green, and #four/blue to be the most common desolder wire.

- #5/brown is ideal for removing large blobs of solder and #6/ruddy is best for desoldering BGA pads or terminals.

- Continue 3 or four different widths at your work area to cover all cases.

- Wick tin exist folded or trimmed at an angle to better fit the contact area.

ESD-condom bobbin for v' and 10' solder wick

Spool common for bulk lengths of solder wick

Common types of flux coating on solder wick:

- Rosin – Rosin-fluxed desoldering wick has the fastest wicking action but does go out behind residues that need to be thoroughly cleaned.

- No-Clean – No-clean fluxed desoldering wick is ideal when cleaning isn't practical or possible. Subsequently desoldering, the only affair that remains is a clear, non-ionic residue. For field work, when a thorough cleaning is more challenging, this is the type of braid to use.

- Unfluxed – In a product or repair environment where the flux is specified and tin't be changed, or when an aqueous flux is needed, you can add your own flux to this type of braid. Unfluxed wick volition not remove solder unless flux is added. Dissimilar types of fluxes are available in pen packaging, which is platonic for fluxing braid.

- Solder wick can also be packaged in a variety of lengths. 5' and 10' lengths are handy for use at a piece of work station. Static dissipative spools, also called "bobbins", are available to prevent dissentious components sensitive to ESD. Longer spools, like 25' (7.6M), 50' (xv.2M), 100' (30.5M) and 500' (152.4M), are commonly stored in a more than central location and dispensed to technicians as needed.

- Other specialized braid designs are also available. For case, Chemtronics offers Solder-Wick Atomic number 82-Gratis, which is engineered to heat faster, and then minimizes thermal shock for high-heat lead-free applications.

Associated products:

https://www.chemtronics.com/desoldering-complect-wick

Can I add my own flux to solder wick?

In a production or repair surround where the flux is specified and can't exist inverse, or when an aqueous flux is needed, you tin can add your ain flux to this type of complect. Unfluxed wick will not remove solder unless flux is added. Different types of fluxes are bachelor in pen packaging, which is platonic for fluxing braid.

For example, Chemtronics offers the following flux pens:

- No-Clean Flux Pens - This no-clean flux is formulated to perform at the elevated temperatures of lead-complimentary soldering only is too effective for tin-lead soldering besides. Information technology's designed with a low surface tension to prevent bridging. Post-soldering cleaning is optional considering the light residue left after soldering is barely noticeable is non-corrosive and halide free. This is a good choice for can-lead soldering where cleaning is to exist avoided.

- Rosin Flux Pen - This is a loftier solid type R rosin flux which provides excellent solderability in a wide variety of applications. The residue left behind is non-corrosive and is halide-costless, simply information technology is all-time to remove the residual after soldering for aesthetics.

- Water Soluble Flux Pen - This is a very active pH neutral ORH1 flux. Information technology enables easy soldering of both pb-free and lead-containing solders. This flux must be cleaned and can exist removed easily with DI water, like in a batch or in-line arrangement, or benchtop cleaning with Flux-Off® Water Soluble Flux Remover.

Associated products:

https://www.chemtronics.com/desoldering-braid-wick

https://www.chemtronics.com/circuitworks-fluxes-and-flux-pens

6 tips for efficient, high quality desoldering.

-

Keep Your Soldering Atomic number 26 Tip Make clean and Tinned For Effective Heat Conduction

This might seem like a no-brainer, but information technology's often disregarded and critical for efficient desoldering. Soldering atomic number 26 tips covered with burnt flux and oxidation will not wet (have solder) and will conduct heat poorly. A make clean and tinned soldering tip conducts heat through the desoldering braid ameliorate and starts the wicking action faster.

-

Minimize the Length of Time That the Board and Components Remain at a High Temperature

Applying high heat levels to the lath or its components for an extended period of time can damage your board, components, create brittle solder joints, and lead to service issues downwardly the round.

-

Match Wick Width to Solder Joint or Contact Pad

Desoldering wick generally comes in several different widths so you can match the braid to what you are desoldering. Wick that is too sparse won't remove enough solder and requires yous to trim and remelt the solder over and over. Wick that too wide takes longer to estrus and may interfere with other components on the excursion board.

-

Friction match Soldering Atomic number 26 Tip to Braid Width for Accuracy

Use a soldering tip that is roughly the width of the braid and contact area. A tip that is also pocket-size will require more than dwell time. A tip that is too large runs the gamble exposing other components in a dumbo associates. Matching the tip size allows you to melt the unwanted solder faster and minimizes the time that heat is applied. Utilize a bract or knife tip when desoldering large areas, like a BGA pad.

-

Match Flux Type to Your Cleaning Process

Desoldering complect is available in various flux types depending on your cleaning process and other requirements. Rosin fluxed complect has the fastest wicking action but leaves behind residues that need to be thoroughly cleaned. No-make clean fluxed complect is ideal when cleaning isn't practical or possible. After desoldering the only affair that remains is a clear, non-ionic residue. For field work, when thorough cleaning is more challenging, this is the type of braid to use.

-

Protect Your Board Confronting Corrosion By Using a Quality Flux Remover

Flux residues tin can cause dendritic growth and corrosion on PCB assemblies, and so make sure you lot're using best practices and clean the lath. After all the components accept been replaced and backlog solder removed clean the area thoroughly with a quality flux remover.

Associated products:

https://www.chemtronics.com/desoldering-braid-wick

How exercise I remove excess solder from BGA pads later on removing the component from the PCB?

Big amounts of solder on large pads or ball grid arrays (BGAs) can be removed using a solder sucker and hot air, merely that requires exposing the PCB to high temperatures for an extended period of time, which can thermally stress other components and the lath equally a whole.

Solder wick is a faster and less thermally stressful method of removing solder from a large area. Solder wick is available in wider configurations, from 3 to over 5mm. 3.5 to 4mm width is identified equally #five or chocolate-brown wick, and 5 to five.5mm equally #6 or red wick. The soldering tip geometry should be matched equally closely as possible to the width of the braid. Tips with a large flat surface, such equally a screwdriver, chisel, bevel, or knife shape, tend to work best. Many technicians brand the mistake of holding the soldering tip on the surface of the braid and then dragging the braid across the pads to remove the molten solder. The dragging motion can scratch the surface of the pads or the OSP coating. The following is the best-practices technique that we recommend:

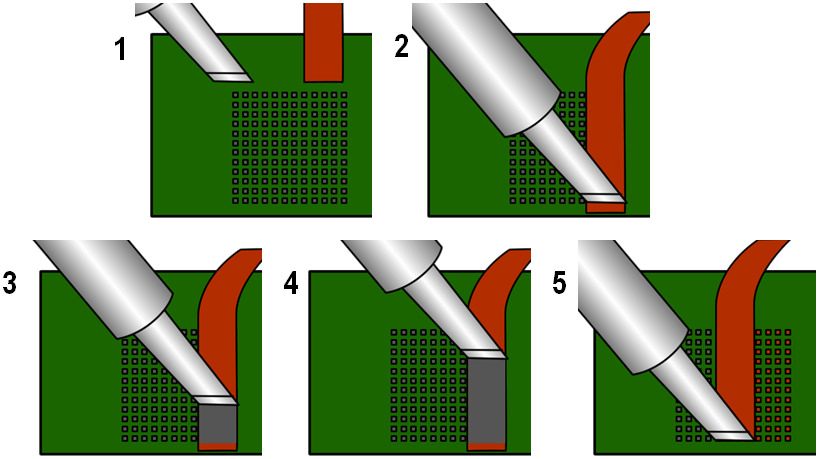

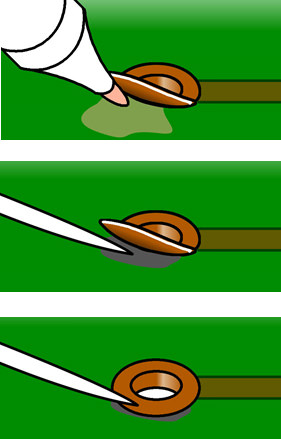

- Apply the braid over the pads to be desoldered.

- Apply the hot soldering tip on one end of the braid (step 2).

- Holding the complect still, elevate the soldering tip up the complect (steps 3-4). At that place is no need to apply pressure on the iron. That simply risks pulling the braid and scratching pads. The weight of the soldering iron should be enough to do the job.

- Lift the braid while it is still hot and echo the higher up steps on the side by side row of pads (step 5). Make certain to trim off spent braid earlier moving to this stride. Excess complect acts equally a heat sink, then it will take longer to heat upward.

Associated products:

https://world wide web.chemtronics.com/desoldering-complect-wick

How do y'all make clean PCBs afterwards soldering?

How practice you remove solder flux?

The virtually common manner to clean flux residues from a repair expanse is to saturate a cotton or cream swab with isopropyl alcohol or some other cleaning solvent and rub it around the repair surface area. While this may exist acceptable for no-clean flux, where the goal is a visually clean PCB, this may not be clean plenty when more than heavily activated fluxes are involved, similar RA or aqueous. The dirty petty hole-and-corner is that flux residues will not evaporate along with the solvent. You may dissolve the flux, and some of the residues will soak into the swab, but about of the residues will settle back onto the board surface. Many times these white residues are more than difficult to remove than the original flux.

Flux residues don't evaporate along with the solvent.

One quick and like shooting fish in a barrel improvement to this process is to rinse the board afterward swabbing around the repair area. While the solvent is all the same moisture, spray over the unabridged board with an aerosol flux cleaner. Concord the PCB at an angle to allow the solvent to period over the lath and run off along with any residues that are picked up.

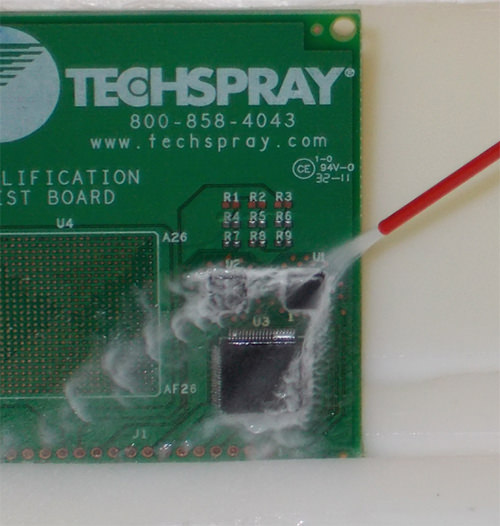

The straw zipper that comes with aerosol flux removers is a good style to increase the spray forcefulness and penetrate below components.

Aerosol with straw helpful for cleaning under components

Chemtronics offers the BrushClean system with many of their flux removers. The cleaning solvent sprays through the brush, and then agitation can be increased past scrubbing while spraying. To absorb the flux residues, a lint-free poly-cellulose wiper tin can be placed over the repair area, and the spraying and scrubbing can occur over the material. Then remove the wipe and brush attachment, and spray over the board for the final rinse.

Aerosol brush attachment over a wiper dissolves and absorbs flux residues at the same time.

Associated products:

https://www.chemtronics.com/flux-removers

https://www.chemtronics.com/circuitworks-flux-remover-pens

https://world wide web.chemtronics.com/chemtronics-cottontip-swabs

https://www.chemtronics.com/chemtronics-controlwipes

How practise yous connect a temperature-sensitive component without high temperature soldering?

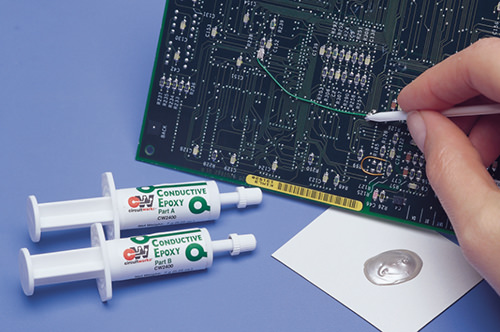

Two-role conductive epoxy is a swell solution for making solderless electronic connections. This type of epoxy contains conductive textile then, when cured, it forms a very potent and highly conductive bond like to a solder joint. Chemtronics offers two options: CircuitWorks® Conductive Epoxy, which cures in 10 minutes, and CircuitWorks® 60 Minute Conductive Epoxy, which provides more time to piece of work. Both Epoxies have A and B components that need to be thoroughly mixed before the curing procedure will begin. In one case mixed, you use the included plastic pick to apply epoxy to the connectedness. If movement may occur during the curing process, y'all will need to tape down or otherwise secure the wires or components.

Conductive epoxy used to attach a jumper wire.

Associated products:

https://www.chemtronics.com/circuitworks-conductive-epoxy-2

How do you lot remove conformal coating when repairing or reworking a PCB?

The best method of removing a coating depends on the type of coating and the sensitivity of the components:

-

Acrylic (AR) / Silicone (SR) / Urethane Coatings (UR):

When desoldering, information technology is possible to fire through Acrylic, Silicone or Urethane coatings. This could go out burned or crude edges that volition demand to be cleaned up before recoating. These coatings can be removed chemically, using either specialized solvents or common solvents, similar acetone, toluene, and xylene. All of these are very harsh (which is why they dissolve coatings so well), and toluene and xylene accept toxicity bug, so brand sure to clothing appropriate PPE and have acceptable ventilation.

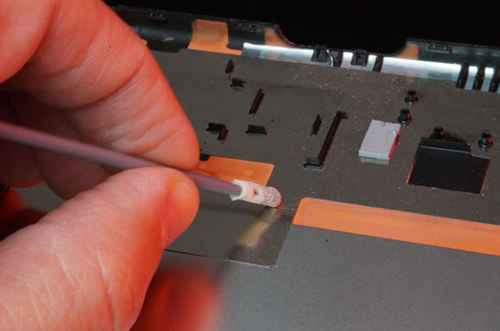

Chemtronics offers the CircuitWorks® Conformal Coating Remover Pen that allows you to remove a precise coating piece without affecting the rest of the PCB. You lot get-go saturate the tip by borer information technology lightly on a surface, which opens the valve and releases solvent. Don't hold it downwardly as it may oversaturate it, which could atomic number 82 to solvent flowing into unintended areas.

You then rub the pen tip over the coating that yous desire to remove. Y'all may need to periodically wipe the pen tip on a wiper to remove accumulated resin. The tip will continue to resaturate every bit you apply pressure as yous clean. Don't press difficult as it could lead to excessive solvent flowing over the board. Let the solvent practise the work, and give it the fourth dimension necessary to interruption down the coating resin. Acrylic blanket will break downwardly chop-chop, but silicone and especially urethane will take more fourth dimension.

-

Epoxy Resin (ER) / Parylene (XY):

Epoxy and parylene coatings are incredibly tough coatings, and resistant to physical and chemical stresses. Of course, the properties that brand them so effective as well make them difficult to remove. You can't strip these resins using a chemic. Burning or melting them off may be possible, but risks dissentious the PCB also. The micro-abrasive diggings method is generally the accepted way of removing epoxy and parylene coatings.

Micro-annoying blasting uses a specialized device to blow abrasive particles over the coated surface. The abrasive medium needs to be chosen with smashing care and then the procedure doesn't impairment the remaining surface, components or markings. The area around the repair should exist masked to isolate the effect of the blasting.

-

Ultra-Sparse Blanket (UT):

Ultra-thin coating, which is condign more common for consumer electronics like mobile phones, should not accept to be removed. It is invisible to the naked eye, and hands burns and scrapes away.

Associated products:

https://www.chemtronics.com/circuitworks-conformal-coating-remover-pen

How do I patch the conformal blanket after a PCB repair?

Ideally, you should utilize the aforementioned coating material every bit the original PCB associates, which should be specified in the service manual of the device. In the real world of electronic repair, you may have no thought what was originally applied. In that case, the easiest solution is to coat using an acrylic blanket.

Chemtronics offers CircuitWorks® Overcoat Pens in a multifariousness of colors to match the PCB resist. Overcoat pens are basically acrylic conformal blanket in convenient packaging, and the clear version can be used to coat small areas. Simply printing downwards the pen tip and squeeze the barrel to manipulate the coating material. For larger areas, conformal coating tin be applied using a small acid brush.

No thing how you coat, make certain you lot avoid coating connectors. Glaze effectually them, or mask them with Kapton tape or temporary solder mask.

Associated products:

https://www.chemtronics.com/circuitworks-overcoat-pens

https://www.chemtronics.com/konform-ar

https://www.chemtronics.com/chemask-peelable

How do you repair a broken trace on a PCB?

A mutual method of repairing a broken trace is to solder on a jumper, which is basically a wire bypass around the broken trace. This can be time-consuming and visually unappealing. Chemtronics offers CircuitWorks® Conductive Pens which incorporate a highly conductive cloth like silver or nickel suspended in a liquid polymer. These pens let y'all to literally redraw the trace.

These are the steps to quickly and effectively repair a trace with a conductive pen:

- For good electrical continuity, you need some expanse of the original trace exposed. If in that location is solder resist correct upward to the suspension, utilise a sharp bract to scrape away about a i/16" portion of the resist.

- Make clean the expanse with either a swab saturated with a solvent cleaner like isopropyl alcohol (IPA) or a CircuitWorks® Flux Remover Pen.

- Vigorously shake the conductive pen until you hear the internal ball rattle.

- Press the pen tip at the break area and squeeze the pen barrel to dispense the conductive ink.

- Allow the conductive ink at to the lowest degree one hour to cure before repairing the overcoat.

- Apply a CircuitWorks Overcoat Pen to repair the resist surface area in the intermission area. Overcoat pens come up in a variety of colors to match the colour of the PCB. Printing downward the pen tip and squeeze the butt to dispense the overcoat cloth.

Associated products:

https://www.chemtronics.com/circuitworks-conductive-pen

https://www.chemtronics.com/circuitworks-conductive-pens-paint

https://world wide web.chemtronics.com/circuitworks-flux-remover-pens

https://www.chemtronics.com/circuitworks-overcoat-pens

How do you repair breaks in EMI or RF shielding?

CircuitWorks Conductive Paint is a single component, silver-filled polymer that dries in minutes at room temperature, making it an ideal solution for patching EMI/RFI shielding. The kit comes with brushes, swabs, and a plastic pick to repair large and small areas.

In the case of metal screen and wire mesh, it is important that the holes in the screen or mesh are significantly smaller than the wavelength of the electromagnetic radiation being kept out. The goal of such mesh designs is to maintain a consistent hole pattern with a conductive material to ensure electric continuity. Such a mesh can be repaired by restoring the hole pattern using polyimide tape and CircuitWorks Conductive Paint.

Simply apply the polyimide record to the inside of the mesh and carefully restore the mesh pattern with the CW2205. It is important to ensure that the contact is maintained betwixt the mesh and the conductive pigment. A second layer of polyimide record can be applied to the opposite side for increased durability. Since the polyimide tape is invisible to electromagnetic fields at these wavelengths, the polyimide tape can remain and the EMI shield is restored.

Figure 1: Damaged screen mesh tin be repaired with polyimide tape and conductive paint.

Another mutual state of affairs is that the aluminum foil within the shielded cablevision is damaged. Similar to the case above, this will cause a loss of continuity and could again allow electromagnetic interference. A uncomplicated repair in this instance is to repair the hole or tear with polyimide tape and then use the CircuitWorks Conductive Paint to paint the tape and restore continuity.

Associated products:

https://world wide web.chemtronics.com/circuitworks-conductive-pens-paint

How do you repair a damaged pad on a PCB?

Standard two-function epoxy tin can contaminate the surface of the connector, creating an insulative bulwark. 2-office conductive epoxy is a great solution for repairing damaged pads. This type of epoxy contains conductive material, then when cured, information technology forms a very strong and highly conductive bond, like a solder joint. Chemtronics offers two options: CircuitWorks® Conductive Epoxy, which cures in 10 minutes, and CircuitWorks® threescore Minute Conductive Epoxy, which provides more fourth dimension to piece of work. Both Epoxies take A and B components that need to be thoroughly mixed before the curing process will begin. In one case mixed, yous utilise the included plastic choice to apply the epoxy to the connection.

To repair a lifted pad:

- Clean the area with either a swab saturated with a solvent cleaner like isopropyl alcohol (IPA) or a CircuitWorks Flux Remover Pen.

- Apply the mixed conductive epoxy under the pad with the supplied plastic selection.

- Press down the pad.

- Allow the epoxy to fully cure before soldering to the pad.

To supercede a damaged pad:

- Cut away the damaged pad.

- For good electric continuity, y'all demand some surface expanse of the original trace exposed. If at that place is solder resist right up to the break, employ a abrupt bract to scrape away nigh a 1/16" portion of the resist.

- Clean the expanse with either a swab saturated with a solvent cleaner like isopropyl alcohol (IPA) or a CircuitWorks Flux Remover Pen.

- Apply the mixed conductive epoxy under the pad with the supplied plastic pick.

- Press downwardly the pad.

- Employ additional epoxy between the pad replacement and the exposed trace.

- Allow the epoxy to fully cure earlier soldering to the pad.

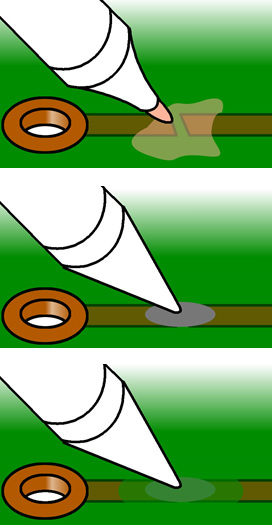

To repair without a pad replacement:

- Cutting away the damaged pad.

- For adept electric continuity, you need some surface area of the original trace exposed. If there is solder resist right upwards to the suspension, employ a abrupt blade to scrape away nearly a i/16" portion of the resist.

- Clean the expanse with either a swab saturated with a solvent cleaner like isopropyl alcohol (IPA) or a CircuitWorks Flux Remover Pen.

- Utilise the mixed conductive epoxy over the pad-less area with the supplied plastic selection.

- Identify the component pb into the epoxy. For a thru-pigsty atomic number 82, it can be formed into a brand-shift gull-wing or J-pb to provide more surface area for the epoxy to grip. Additional epoxy can be practical over the atomic number 82 for actress security.

- Allow the epoxy to fully cure earlier handling the PCB.

Associated products:

https://www.chemtronics.com/circuitworks-conductive-epoxy-2

https://www.chemtronics.com/circuitworks-flux-remover-pens

How do you repair a PCB crack or open area of the solder resist on a PCB?

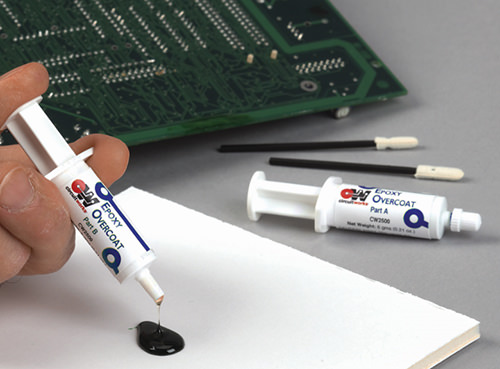

This respond assumes the crack does not touch surface or inner-layer traces. CircuitWorksOvercoat Epoxy provides a rugged repair that can in fact reinforce PCB areas with more than structural cracks. To use:

- Make clean the area with either a swab saturated with a solvent cleaner like isopropyl alcohol (IPA) or a CircuitWorks Flux Remover Pen.

- Mix equal amounts (1:ane) by book of Part A and Part B. Mix thoroughly for one infinitesimal.

- Utilise a brush or pick to apply the epoxy. Pot life is xv-20 minutes at room temperature.

- Tack gratis time is later on 30 minutes at room temperature. Excellent results have been obtained by curing for 10 minutes @ 100°C. Optimum cure cycles using radiant or convection conveyer ovens are all-time adamant experimentally. Product may too be cured for 24 hours @77°F (25°C).

- Clean-Up/Removal (uncured): Use isopropanol, acetate, or MEK to clean-up uncured resin. Cured Epoxy Overcoat cannot be removed using solvents.

Associated products:

https://www.chemtronics.com/circuitworks-epoxy-overcoat-adhesive-syringe

https://www.chemtronics.com/circuitworks-flux-remover-pens

What flux should I employ when replacing PCB components?

Flux is needed to preclude oxidation that tends to class when hot metals run into air. During printed excursion board repair and soldering, it's common to run into liquid flux from the moving ridge soldering equipment poured into jars and practical with an acid brush. That tin atomic number 82 to applying likewise much flux, forcing an additional cleaning stride that might not otherwise be necessary. Other types of flux and special packaging are bachelor that are better suited for PCB repair:

-

Flux Pen - Flux pens are valved, prefilled pens of flux. Flux pens avoid the mess and hassle involved in filling your own flux bottles. A flux dispensing pen contains the flux in the airtight barrel of the pen. They are an excellent way to dispense flux for benchtop soldering. You simply hold the pen vertically and briefly depress the tip to beginning the liquid flow. This will saturate the tip of the pen with flux, then you depict flux on the area to exist soldered. Gently printing the tip again to keep the tip damp with flux.

CircuitWorks® flux pens are bachelor with a diversity of fluxes to fit your specific shop requirements including: no-clean, high temperature no-clean for lead-complimentary soldering, rosin, and water soluble.

-

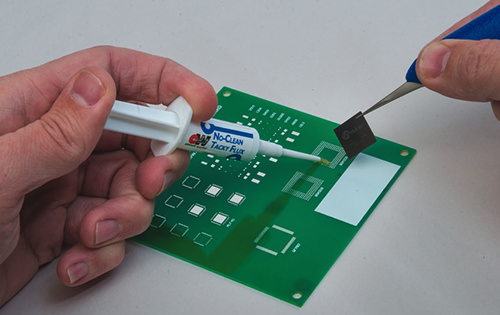

Tacky Flux - Tacky flux is a viscous, pasty form of flux that is easy to place without it spreading into surrounding areas the way a liquid flux tin. It can exist used to hold pocket-size parts in place before soldering and is common in the industry and repair of SMT components. Tacky fluxes in syringe dispensers provide for dispensing convenience similar to a pen only when tacky flux is more than appropriate. The thick, honey-like consistency is ideal for brawl-adhere applications, BGA re-balling and mitt soldering SMT components. The flux is dispensed from a syringe and tin can be spread over the desired area for soldering.

CircuitWorks® No-Clean Tacky Flux is a mildly activated rosin (RMA) no-clean tacky flux. Its conception includes a unique rosin/resin-blend coupled with a proprietary blend of activators and stabilizers providing both significantly increased shelf life and long-term production stability. The remaining residue is stable and can be left on a lath without cleaning, or tin can be hands removed with Flux-Off® No-Make clean Plus Flux Remover. CircuitWorks® Lead-Complimentary Tacky Flux is formulated for higher temperatures common in lead-free soldering.

Associated products:

https://www.chemtronics.com/circuitworks-fluxes-and-flux-pens

Is in that location a quick fix for cold solder joints?

A "cold" solder joint is mostly grainy, which is a sign that the solder didn't melt and wet properly, and then y'all may not have a expert metallurgic bail. The connexion will most likely break loose with any corporeality of physical or thermal stress. Exist warned that graininess is a visual cue for only lead-based solders. Lead-gratis solders oft wait grainy even when there is a good metallurgic bond.

The quickest manner to prepare a cold solder articulation is to simply use a solder iron to remelt the solder. The flux will have been fully activated in the original soldering process, so additional flux can be added using a CircuitWorks® Flux Pen.

- Lightly printing the Flux Pen tip to the solder joint until the tip saturates and the flux flows.

- Rub saturated Flux Pen tip over the solder joint.

- Use the heated solder tip to the solder joint to remelt it.

- If necessary, clean flux residues with either a swab saturated with a solvent cleaner similar isopropyl alcohol (IPA) or a CircuitWorks Flux Remover Pen.

Associated products:

https://www.chemtronics.com/circuitworks-fluxes-and-flux-pens https://world wide web.chemtronics.com/circuitworks-flux-remover-pens

How do you repair black carbon conductor button pads on PCBs?

Chemtronics offers the CircuitWorks® Rubber Keypad Repair Kit, which tin can be used to repair keypads by restoring electrical conductivity to worn, intermittent, and nonconductive carbon contacts. Information technology is a two-part mix, and comes with a swab, brush, and plastic pick to assist with mixing and applying the materials.

To set black carbon conductor push pads:

- Clean the surface area with either a swab saturated with a solvent cleaner like isopropyl alcohol (IPA) or a CircuitWorks Flux Remover Pen.

- Pour the liquid in Part B into the container of Function A. Stir thoroughly for two minutes.

- Paint the worn carbon contacts with the mixed conductive material using the enclosed applicator brushes. Use the least amount of conductive fabric every bit possible.

- At room temperature (<75°F / 25°C), the textile dries tack-free in one hr. Repaired keypads tin be returned to service in 24 hours. Ultimate properties are achieved in 72 hours. For faster drying, expose the textile to approximately 190°F (90°C) for x minutes. Do not exceed 212°F (100°C).

Associated products:

https://world wide web.chemtronics.com/circuitworks-safe-keypad-repair-kit

https://www.chemtronics.com/circuitworks-flux-remover-pens

Is there a good way to remove labels and sticky residues?

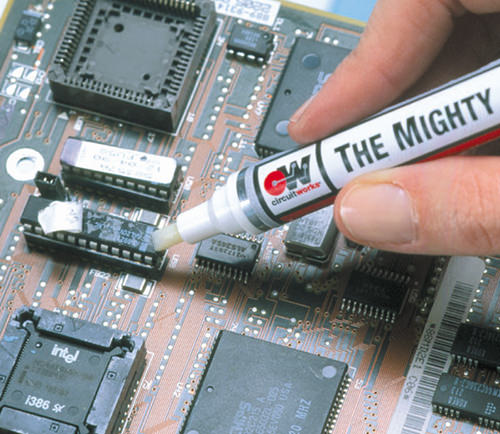

Old identification or QC fault labels can be difficult to remove. They either exit viscid agglutinative behind that is insoluble by commonly available solvents like isopropyl booze (IPA), or are so dried and baked-on that they won't budge. While consumer products like Goo Gone or bug-and-tar remover are common to run into on workbenches, Chemtronics offers a cleaner that is actually intended for PCB repair called The Mighty Pen®. Information technology contains a fast acting solvent that breaks down stale and sticky adhesives.

How to use The Mighty Pen to remove labels:

- If the label is plastic or covered by a picture show laminate, you may have to peel it up to permit solvent to penetrate underneath.

- Lightly press the pen tip on the label until the tip saturates enough for solvent to start to catamenia.

- Rub saturated pen tip over the characterization expanse and permit it to soak through.

- Let the saturated characterization to sit for at least 15-twenty seconds, then rub the expanse with pen tip until the label material and adhesive are removed.

- Wipe area with clean wiper to remove agglutinative residue and solvent.

- Reapply solvent as necessary or allow more than soak time for stubborn adhesives.

- If at that place is adhesive build-upward on pen tip, wipe it with a clean wiper.

Associated products:

https://www.chemtronics.com/circuitworks-the-mighty-pen

Source: https://www.chemtronics.com/ultimate-guide-to-benchtop-pcb-rework-repair

Posted by: bensonwift1981.blogspot.com

0 Response to "How To Repair Surface Mount Pcb"

Post a Comment